Throughput Estimation:

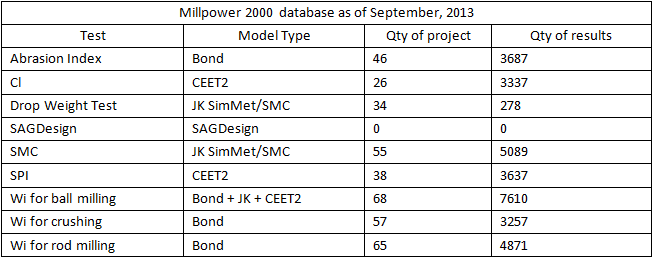

Simulation of Mill Sizing “Millpower2000”

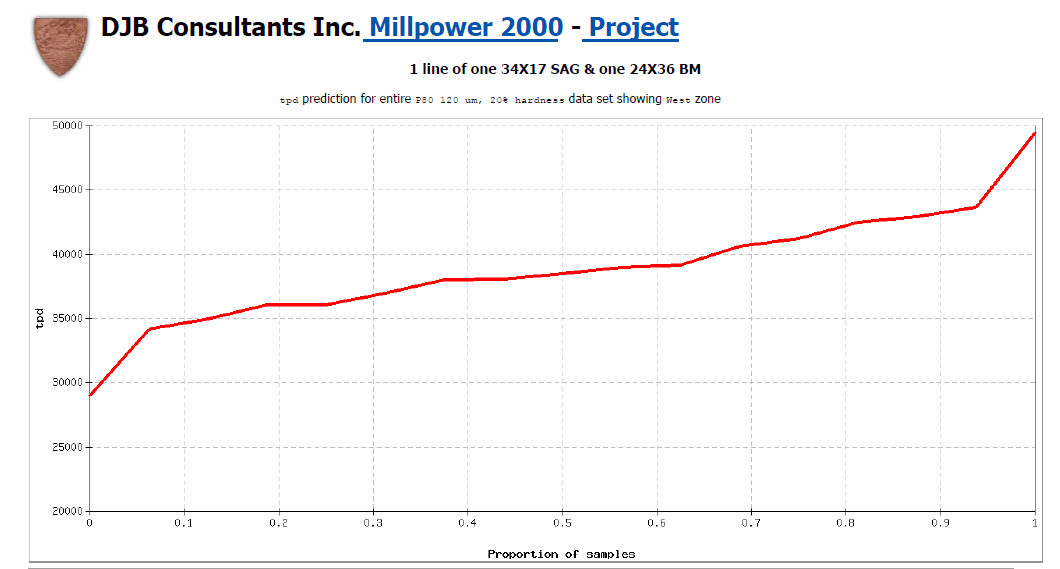

Comminution test results are entered into the “Millpower2000” database (please refer to the table) on a project basis for simulation. Different combinations of mill sizes, motor powers, and operating conditions can be simulated to assess ranges of mill throughput objectives and ore hardnesses on a “sample frequency” basis (please refer to the chart).

Ore Characterization

Objectives

- Geometallurgical variation (mine to mill)

- Economically predict specific power consumption and variation in an orebody

- Permit reduction in design allowances, or capture additional throughput in softer ores.

- Establish the necessity for Pre-Crushing or HPGR.

Testing Ore Composites

- Batch scale required for variability, simulation & design (ore dependent)

- Pilot scale required for autogenous grinding, design (ore dependent) & model calibration.

Calculation & Methodology

Selection of a ‘Design Point’ on the chart will define the required motor powers for the grinding circuit to process hard to soft ore types, consistent with a range of mill throughput within the Payback period and future potential for an expansion which would be determined from entry of data into the mine block model.