Geo-Comminution

SAG Mills, HPGR, Ball Mills & Pre-Crushing:

Specific Energy Requirement and Design

These equations form the Basis of DJB’s “Millpower2000” Simulation Program for estimating power requirements and mill sizes vs mill throughput objectives. It is an iterative process, but the software can accommodate a large number of geo-comminution samples in a time-efficient manner.

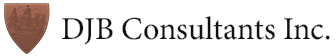

Basic Equations

Empirical Formula (Barratt)

Overall Power Requirement, ASAG Circuit (1979)

Modified power requirement based on El Teniente Surveys (1986)

EBM= (ESSBM * -ESAG) + Contingency (1986)

With a Bond Work index-based Phantom Cyclone Approach (1989)

*ESSBM for secondary/tertiary crushing and single-stage ball milling (Rowland, 1982)

Net power for AG/SAG mills

kW (net) = PN * ρ * D2.5 * L

Legend

PN = power number*

ρ = mill charge density (Loveday, 1979)

D = diameter (net effective inside shell liners/lifters)

L = effective grinding length (inside feed end and grate discharge liners along the mill shell)

*Based on contact (1986-1987) with:

– Highland Valley Copper (Lornex), Afton, Island Copper & Similkameen and update (1992-1993) with:

– Kennecott (Copperton)